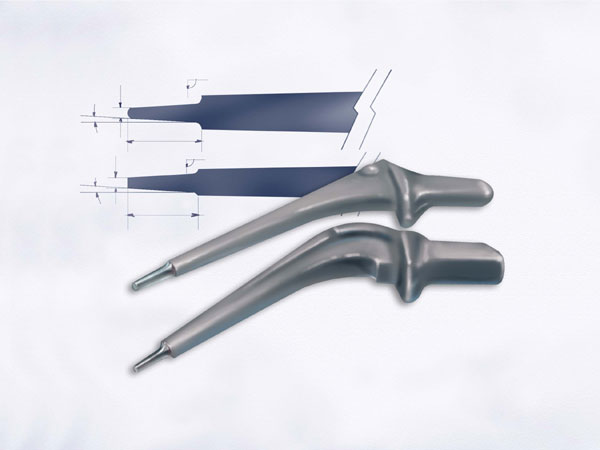

Work piece examples include:

Landing gear assemblies, jet engine turbines, buckets, blades, fuel nozzles and various engine parts.

Case Histories

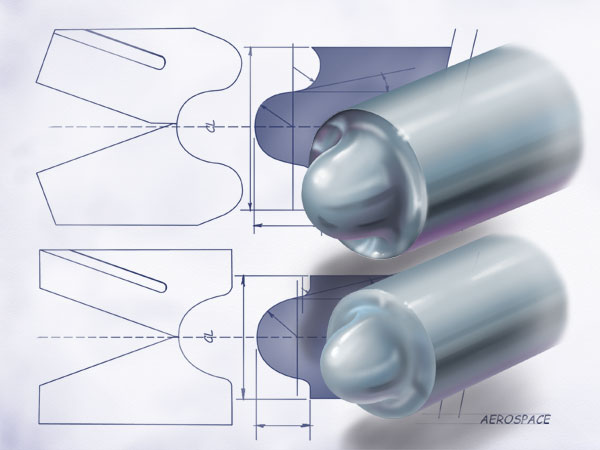

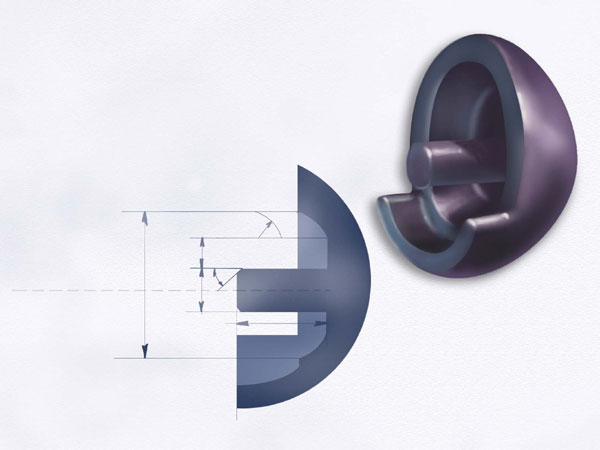

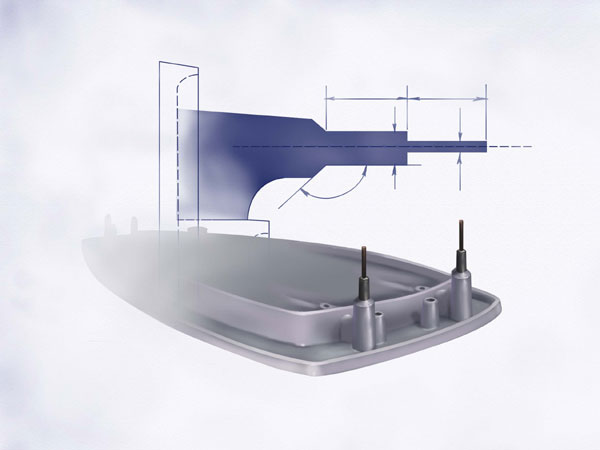

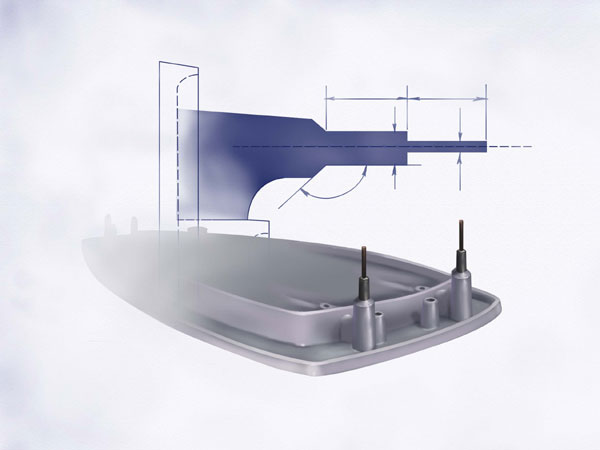

Spherical Ball Seat

A contract manufacturer of both commercial and military aerospace components is required to machine a family of parts from 4340 material at 33Rc hardness.

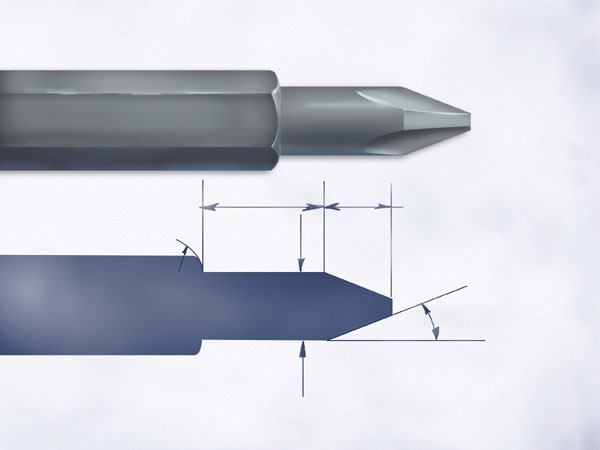

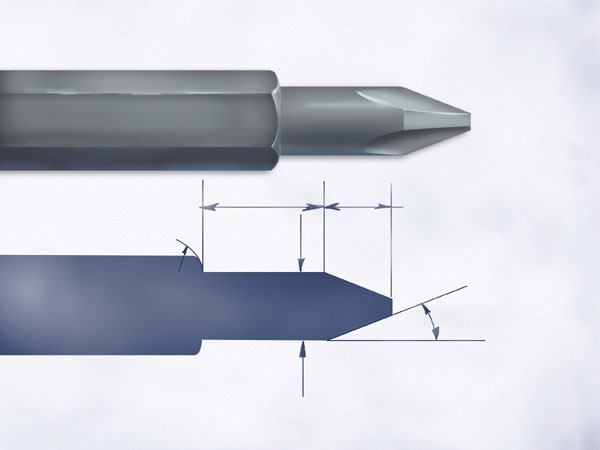

- The form required is a spherical ball seat comprised of:

- a .750 convex radius

- Blended to a 15° taper

- Then blended to a concave radius generally between .190 and .250

- And finally facing at 90° to the component I.D.>

- The parts have in common the .750 concave radius but vary in the length of the 15° chamfer, the size of the concave radius and the amount of the 90° facing required.

THE SOLUTION:

Genesee designed special hollow mills using four precision ground and matched premium T-15 HSS blades, set to cut to centerline to produce the entire ball seat complete in one pass.

- This Genesee hollow mill solution has been in use for decades.

- The technology has remained constant due to the productivity supplied, even during plant and location changes