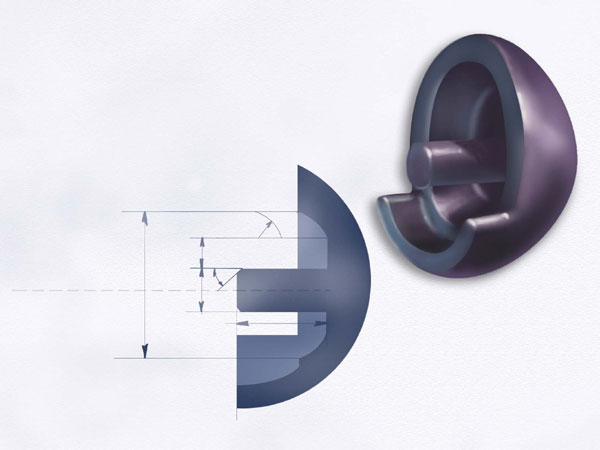

Work piece example include:

Probes, operating sutures, lens housings and precision instruments.

Case Histories

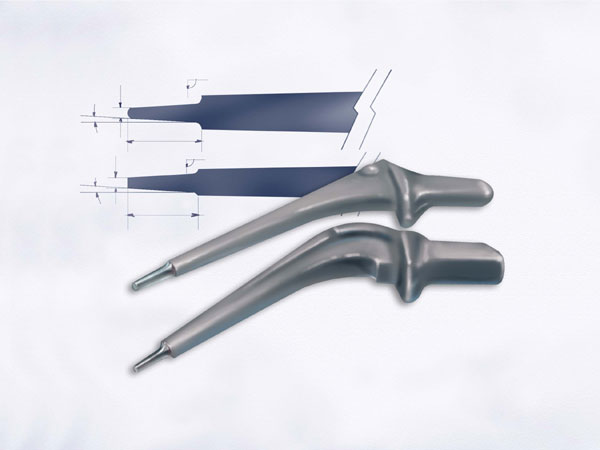

Hip Joint

An American manufacturer of medical parts was required to produce a 3° tapered tip, .515″ long, blended to a .250″ radius on the end of a family of parts.

- The parts were made from difficult-to-machine cobalt chrome material.

THE SOLUTION:

Special Genesee inserted blade tooling using four match ground, brazed carbide blades offered the solution.

- Delivered the desired productivity and consistent size and finish.

Because the family of parts has the same geometry, in different diameter parts, the same tool and blades can be adjusted to machine the entire family of parts.

Shoulder Joint

A shoulder joint was machined using special shaped trepanning blades in a Genesee hollow mill.

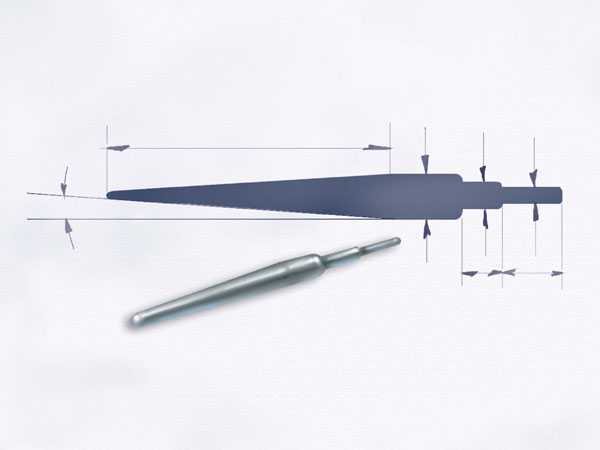

Dental Tool

Dental tool made of surgical stainless steel is machined to produce a 2° taper .925″ long, and .218″ long straight.